Unsere Produkte decken nahezu alle Aspekte der umweltfreundlichen Wasseraufbereitung ab. Von der Filtration, Schlammentwässerung, Abscheidung von Fischläusen und Eiweißabschäumung bis hin zur Sauerstoffanreicherung.

Unsere Kunden sind RAS-Anlagen, traditionelle Fischfarmen, Wellboats, Aquarien und Industrien mit allen Arten von Herausforderungen bei der Abwasserbehandlung.

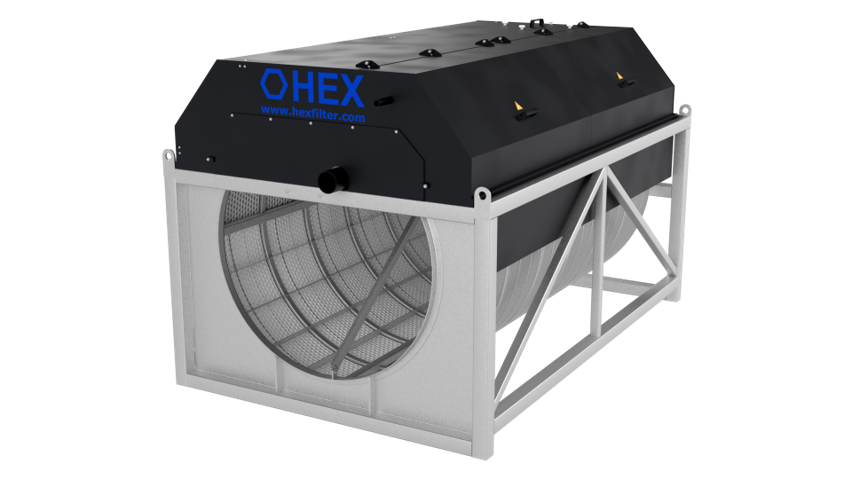

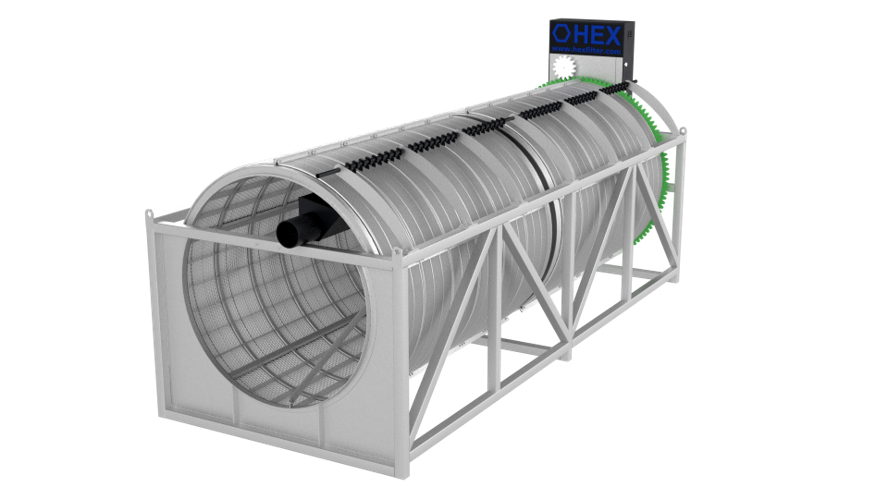

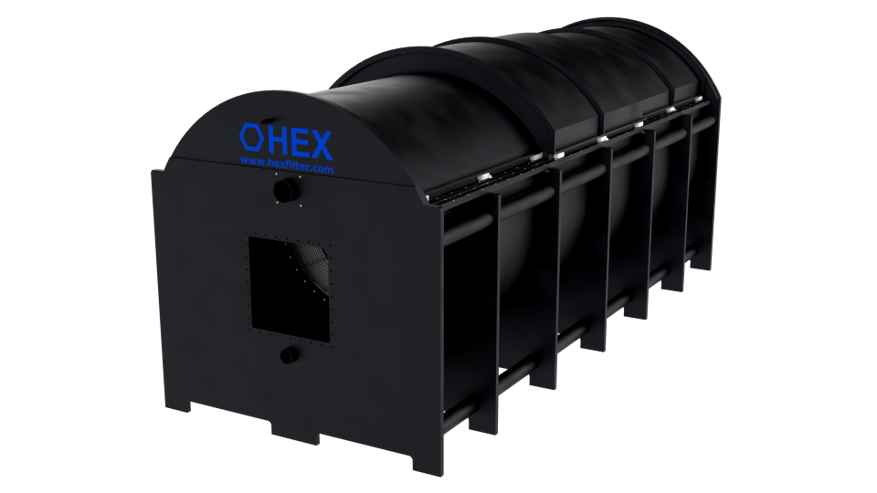

HEX Trommelfilter

HEX-Trommelfilter sind für eine zuverlässige und effiziente Wasserfiltration und Partikelentfernung von 10 bis 500 μm ausgelegt. Eine robuste Konstruktion, keine Schmierung und fast kein Wartungsbedarf garantieren eine lange Lebensdauer. Die patentierte Sechseckform des Stützgitters ermöglicht das Biegen der Filterpaneele ohne singuläre Stranglast. Die Filter sind energieeffizient und werden in verschiedenen Ausführungen und Größen geliefert - angepasst an unterschiedlichste Bedürfnisse.

Mehr erfahren-

HEX Trommelfilter Model F

Standard HEX, sehr robust und kontinuierlich verbessert

-

HEX Trommelfilter Model X

Alle High-Tech-Polymere eignen sich perfekt für Salzwasser und tropisches Salzwasser

-

HEX Trommelfilter Model SHIP

Gebaut für den Einsatz in rauer See mit offenem Zugang und wasserdichtem Antrieb

-

HEX Trommelfilter Model SANI

Spezialisiert für einfache Desinfektion mit ultraschneller Entleerung und schnellem Vollzugriff

Produkte

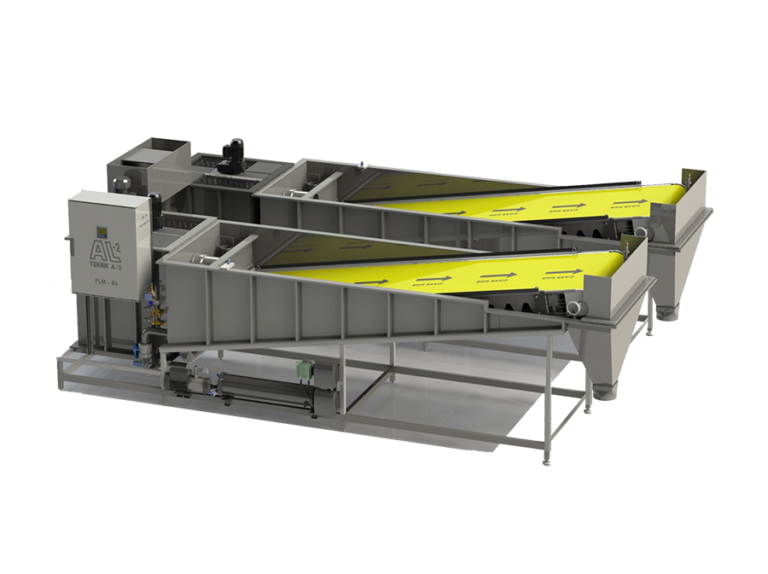

Ratz Aqua & Polymer Technik bietet eine breite Palette von Produkten für die Aquakultur- und Wasseraufbereitungsindustrie. Wir stellen in unserem Werk in Remscheid hochwertige HEX-Trommelfilter und Ratz-Eiweißabschäumer her. Der Vertrieb wird maßgeblich durch unser dänisches Partnerunternehmen CM Aqua organisiert, welches zudem Oxywise-Sauerstoffgeneratoren und AL2-Bandfilter für die Aufkonzentrierung von Schlamm anbietet.

Mehr erfahren